How can simple automation aid manufacturing operators?

Even the most simplistic task can be aided through automation. In manufacturing, operators often have to complete repetitive and time-consuming...

When you think about the manufacturing industry, it's easy to imagine a huge warehouse full of machines and equipment that all work together with precision.

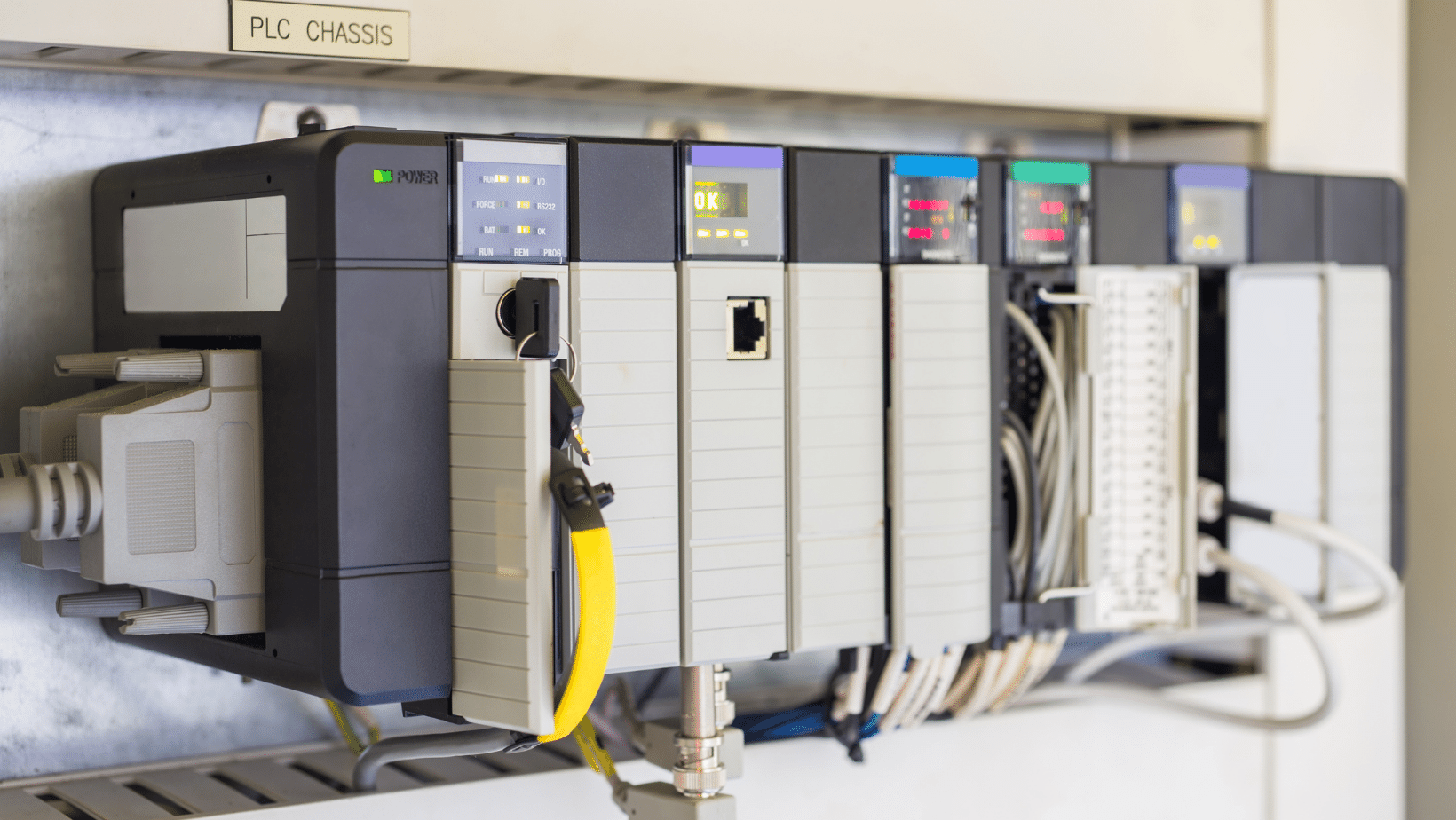

But how do these automated plants know what they're doing? The answer: programmable logic controllers (PLC). These specialized computers can be found running through production lines across industries like automakers or even food processors; ensuring each product gets made correctly according to plan.

Programmable Logic Controllers, or PLCs, are devices that use logic statements to control machines and processes. They are used extensively in industrial automation applications.

PLCs are essentially small computers that can be programmed to control a wide variety of devices and processes. They can be used to monitor and control things like machinery, production lines, conveyor belts, elevators, and even cellular phone networks.

Originally developed for the automotive industry, PLCs are now used in pretty much all manufacturing facilities, in all types of industries, all over the world.

The worldwide market for PLCs reaches $16 billion each year, with a nine-year compound annual growth rate of 9.2 percent. They are capable of being put in place in harsh environments, even those that involve high heat, noise, dust, and other conditions. Without them, factory automation as we know it would be very different.

Automation is the use of various control systems to operate equipment automatically or semi-automatically.

PLCs are used extensively in industrial automation, where they monitor and control things like machinery, production lines, conveyor belts, elevators, and even cellular phone networks. PLCs can be used to control just about anything that moves or changes state—from simple on/off switches to more complex tasks like regulating the flow of oil in an oil refinery.

Most PLCs are built to handle a specific type of process—they cannot be changed without physically taking the PLC apart and reprogramming it. That means an oil refinery will have PLCs made specifically for working with pumps and valves at an oil refinery; they will not work well (or at all) if used in a bakery.

Most PLCs use digital input and output (I/O). This means that the PLC can read data from sensors and switches, and also send data to devices like motors, valves, and lights.

Typically, an operator alerts a PLC that a certain task needs to be done—for example, starting a machine. The PLC will then execute a program that will start the machine and continue to monitor it while it is running.

If something goes wrong with the machine, the PLC can stop it, or take other corrective action as needed.

PLCs are usually controlled by a computer or another device running special software. This software allows the user to create and edit programs, as well as monitor the status of the PLC.

PLCs use a programming language that is specific to the PLC make and model. This language allows the user to create logic statements, or "rules," that dictate how the PLC should behave. For example, a rule might tell the PLC to turn on a pump if the pressure in a tank falls below a certain level.

One critical component of a PLC is the human machine interface (HMI). The HMIs are screens, buttons, and knobs that allow operators to monitor and control the PLC. Depending on the complexity of the PLC, it might have very few HMIs—or hundreds.

Most HMIs are programmable as well, so they can be customized to the specific application. The software used to create or edit programs is also used to design or configure HMIs. This means that operators can control all aspects of a PLC from a single interface.

PLCs can be used in any industry where machines or processes need to be controlled. Each industry has its own specific needs, and as a result, each industry has its own preferred PLC manufacturers.

They are most commonly found in the following places:

Because of their resistance to damage from high-pressure and high-temperature conditions, PLCs are ideal for use offshore and at refineries.

For example

PLCs are often the brains of modern BOP control systems. A blowout preventer, or BOP, is a large specialized unit is used to prevent an oil spill from occurring. It works like a valve to close an oil well, similar to a plumber closing a valve in a pipe, and are proven to be highly effective in ensuring good safety.

PLCs are used extensively in manufacturing to automate and/or control machines and processes, like at PLC. They receive input from a variety of sensors and switches, create a sequence of actions based on this information, and then send signals to the devices that will execute these actions.

For example:

If a finished car rolls down a conveyor belt into an assembly area, the PLC might be programmed to

PLCs are also used in the process engineering industry. Process engineers use them to monitor and control chemical, petrochemical, and other similar processes.

These controllers are often used to monitor the status of machinery in chemical plants, water treatment facilities, and other industrial settings.

For example:

PLCs are used extensively in water and wastewater treatment plants to control pumps, valves, and other equipment.

A PLC might be programmed to

The food and beverage industry requires machines that are easy to clean and sanitize. Because of this, many PLCs used in this industry are made from stainless steel or other non-corrosive materials.

PLCs are used in food and beverage plants to control machines that package and process food.

For example:

A PLC might be programmed to

PLCs are used in civil engineering to control machines that lift heavy objects. A crane is a machine that automatically lifts heavy objects, and PLCs are often used for this task.

For example:

A construction company might use SCADA software to monitor its fleet of cranes on all of the projects it's working on. It might also use this system to control the cranes remotely.

Industrial controls use PLCs to automate industrial systems and equipment.

For example:

When choosing a PLC for an application, it's important to select one that is suited for the task. For example, a very complex PLC might be overkill for simple tasks like turning on an LED light.

Some key factors to consider when choosing a PLC are:

PLCs have been around since the late 1960s, and in some ways, they haven't evolved much since then. They fulfill a basic requirement for real-time machine control across a wide range of industries and are an essential component of manufacturing automation culture.

However, as the use of contemporary technologies grows more common in industry, PLC systems appear to be lagging behind.

Factories began incorporating automation technology and sophisticated electronics into their production processes in the second half of the 20th century, launching what is sometimes known as the 3rd Industrial Revolution. PLCs were crucial in this transition from industrial production to Industry 3.0, as well as the adoption of Industry 3.0.

Today, businesses are using internet-connected sensors, sophisticated data systems, and other technologies that fall under the category of "Internet of Things" to implement the concept of a connected world - a process that’s considered to be the 4th Industrial Revolution or Industry 4.0.

Will PLCs remain an important component of production processes, with more firms bringing cyber-physical systems to market? Or will the PLC's demise be near? They are simple to use, trustworthy, proven to work well, and precise, so it's doubtful that they'll be removed or altered in any significant way in the immediate future among small- and medium-sized businesses.

But, as we move into an era where machines are becoming increasingly interconnected and manufacturers are striving for greater efficiency, it's likely that PLCs will need to evolve in order to keep up.

Nevatio Engineering is a full-service automation and controls services provider. Our team of engineers has extensive experience with industrial control systems, process control systems, machine retrofit systems, robotics, EOATs and much more.

You don’t have time to waste on projects that go over budget or fail to meet expectations. That’s why our clients choose us again and again – because they know they can trust us to deliver exactly what they need at the right price every single time! If you want a partner who will work closely with you throughout your project lifecycle, then give us a call today!

Nevatio Engineering is an agile design and engineering consulting team capable of on-demand mechanical and electrical engineering, functional prototyping, engineering documentation, and machine retrofits. We are experts in machine design, special devices, industrial products, jigs and fixtures, plus automation and controls. Our added knowledge in industry design standards such as ASME, ANSI, ISO, NFPA, NEC and BS allows us to quickly integrate our services with your existing standard design processes, keeping your resources free from unnecessary rework.

We specialize in helping industry leaders solve difficult engineering and design problems. Our mission is to empower our clients with the tools and skills necessary to create solutions to their technical problems. With our expertise, clients can address any technical design problems that stand in their way.

We believe in being consistent with our deliveries. This means that we are always on time and able to work for your business needs, no matter what they may be.

Even the most simplistic task can be aided through automation. In manufacturing, operators often have to complete repetitive and time-consuming...

Having industrial automation is a necessity, but there's a lot of gray area when it comes to calculating the benefits. And part of that gray area is...

As industries move towards the fourth industrial revolution, more and more emphasis is being put on machine-to-machine (M2M) integration. This refers...