We believe in being consistent with our deliveries. This means that we are always on time and able to work for your business needs, no matter what they may be.

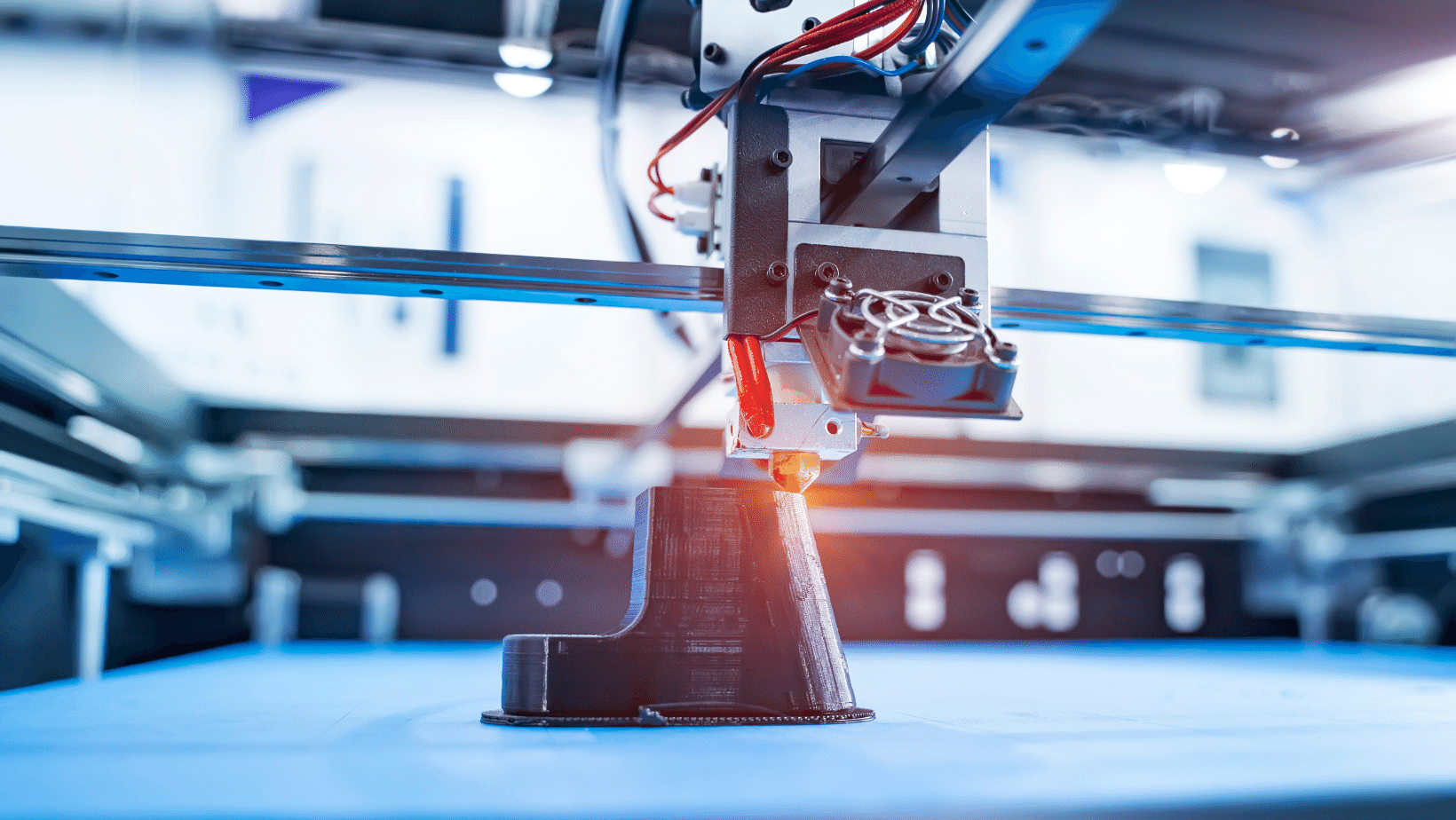

The 3D printing industry has been growing at a rapid pace. With the recent advancements in technology, it's no surprise that more and more companies are turning to this new method of fabrication. One common use for these printers is jigs and fixtures, which help with production by holding parts in place during assembly or machining processes.

Let's discuss some advantages to using a 3D printer for producing jigs and fixtures as opposed to traditional methods, and everything else that you need to know.

Why use fixtures during manufacturing production?

Fixtures can be used to hold a part in place during manufacturing production, but also allow for easy removal of the part after it's been produced. Similarly, jigs allow for better tolerances and reduce human error by eliminating certain steps such as drilling holes and fastening parts together.

Lastly, fixtures can also reduce post-processing, which in turn reduces production time and cost by allowing for quick assembly and removing the need to sand or file a part after production.

Jigs and fixtures are useful for optimizing industrial manufacturing processes, and they have several advantages, including:

- Improving accuracy and repeatability of operations by minimizing scrap material.

- Increasing the amount of output produced over time

How can 3D printing jigs help manufacturers achieve a lean manufacturing process?

Manufacturers are increasingly focused on improving production efficiency and productivity. Conveniently enough, jigs and fixtures are manufacturing tools that can be used to increase the process's dependability, accuracy, and quality while reducing manufacturing cycle times and minimizing employee risk.

3D-printed jigs and fixtures can also help manufactures and engineers achieve a lean manufacturing process due to their unique qualities, including:

- 3D-printed jigs and fixtures allow for lower-volume runs of complex assemblies to be easily produced with no minimum order quantity.

- Fixtures offer a single-piece design to reduce post-processing, increase strength and accuracy.

- Fixtures can be easily designed in a CAD program, iterating the Jig until it's correct.

- 3D printing reduces the amount of time needed to design.

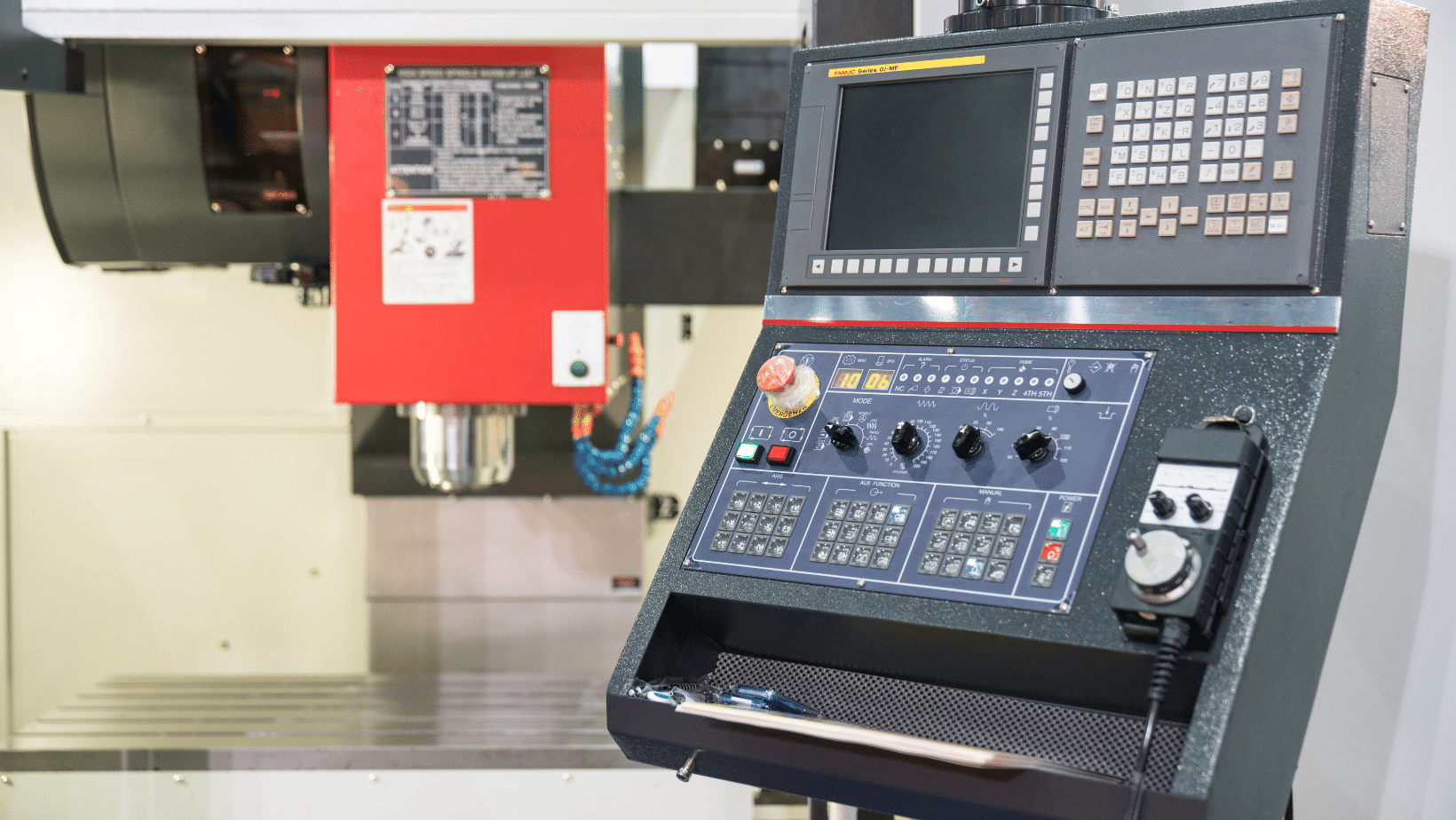

3D Printing over CNC Machining

CNC machining is the most common manufacturing process for creating jigs and fixtures since volumes are typically low.

Even though this process seems to have some popularity, CNC machining has its drawbacks as well: Jigs and fixtures require programming of the CNC machine, which must be done for each order, bringing about long lead times.

Why manufacture jigs and fixtures via 3D Printing?

3D printing offers a unique advantage over CNC machining by reducing lead times, increasing consistency and reliability, and allowing jigs and fixtures to be easily customized, resulting in less post-processing required by jigs.

Here are some reasons why 3D printing is beneficial to manufacture jigs and fixtures:

1. Reduce manufacturing costs

In some cases, 3D printing is the most logical process when the geometry is too difficult or costly to machine. It’s important to note that not all jigs and fixtures need to be made of metal.

2. Lower lead times

Another advantage of 3D printing is the rapidity with which parts may be manufactured. Because 3D printing utilizes 3D CAD designs, all that is necessary is to upload the data to print a part in several hours.

3. Offer improved performance

3D printing can assist designers improve the performance of jigs and fixtures by allowing them to generate new and improved patterns more quickly.

If a part requires a more intricate geometry that is difficult to machine, 3D printing is recommended. For high volume needs, rapid injection molding can produce 25 to 10,000+ parts in a number of engineering-grade thermoplastics.

4. More material manufacturing options

3D printing may be used to create a wide range of items, from polymers and metals to rubbers and waxes. Multi-material 3D printing is a quickly developing area of study, utilizing materials to develop new ones with improved mechanical properties.

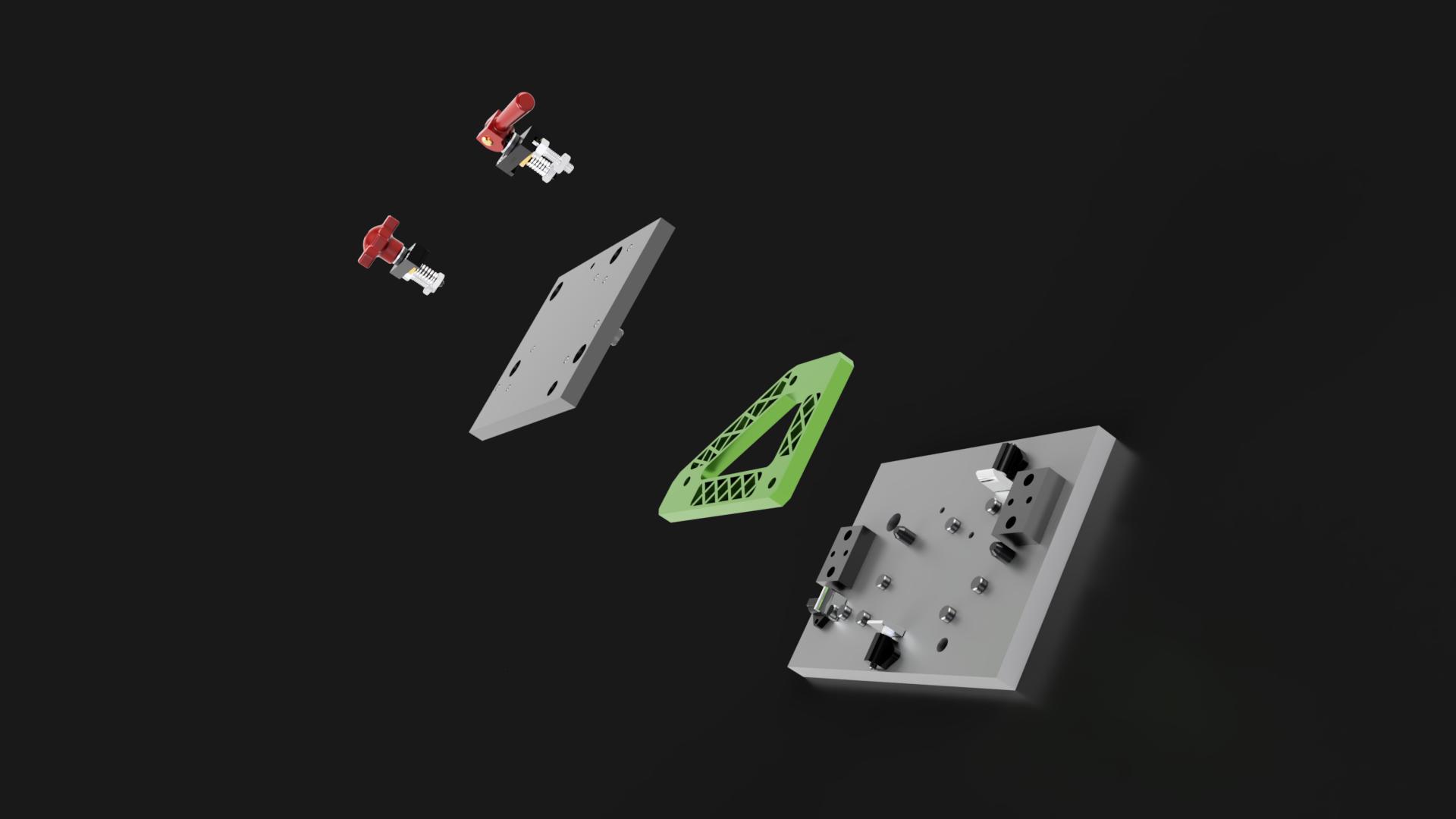

How can jigs and fixtures be designed with 3D printing?

3D printing allows for jigs and fixtures to be faster, cheaper, more consistent, with less waste than traditional manufacturing methods such as CNC machining.

Below, we've outlined the five most popular ways jigs and fixtures are designed with 3D printing.

1. Jigs to Hold Parts Together

3D printing jigs that are used to hold parts together are typically made using multipart assemblies.

Since jigs are typically made from ABS plastic, jigs designed using multipart assemblies can be easily broken down into their individual components for recycling purposes (after the jig is finished holding the part together).

3. fixtures that Ensure Correct Position for Assembly

Some jigs and fixtures are designed to ensure the correct positioning of parts when the jig is removed (for example, CNC fixtures). Jigs with this design feature are typically designed in part to easily attach and detach from the part being manufactured after being used for their original purpose, such as holding together parts during a 3D printing process.

Jigs like these may be made with metal or plastic, depending on if the jig will be subject to high-temperature applications.

Do you need an engineer to design a jig or fixture?

Nevatio Engineering is an engineering and designing company that specializes in creating custom jigs and fixtures.

When in need of a quick turnaround tool for production or prototyping needs, fixtures are often at the top of our list. We can design and deliver reusable tools made to your engineering specifications.

Our engineers are experts at their craft, so they can help you with any project, no matter how big or small. With our expertise, we can take care of everything from concept drawings to final assembly on your product.

References

Jigs and Fixtures: 6 Ways to Improve Production Efficiency with 3D Printing -

https://amfg.ai/2021/05/13/jigs-and-fixtures-6-ways-to-improve-production-efficiency-with-3d-printing/

About Nevatio Engineering

Nevatio Engineering is an agile design and engineering consulting team capable of on-demand mechanical and electrical engineering, functional prototyping, engineering documentation, and machine retrofits. We are experts in machine design, special devices, industrial products, jigs and fixtures, plus automation and controls. Our added knowledge in industry design standards such as ASME, ANSI, ISO, NFPA, NEC and BS allows us to quickly integrate our services with your existing standard design processes, keeping your resources free from unnecessary rework.

We specialize in helping industry leaders solve difficult engineering and design problems. Our mission is to empower our clients with the tools and skills necessary to create solutions to their technical problems. With our expertise, clients can address any technical design problems that stand in their way.

Everything on 3D Printing of Jigs and Fixtures

The 3D printing industry has been growing at a rapid pace. With the recent advancements in technology, it's no surprise that more and more companies...

5 Facts About Machine Retrofit Solutions

After the Great Recession, machine retrofit solutions have become increasingly popular. All CNC machine retrofit solutions are not created equal,...

Understanding CNC Fixtures

You may be familiar with CNC machines (or at least have heard about the subject). Similarly, you may also be familiar with the terms "jigs" and...