End of Arm Tooling Services

End of Arm Tooling Services

Are you looking to build your own EOAT but just need a starting point?

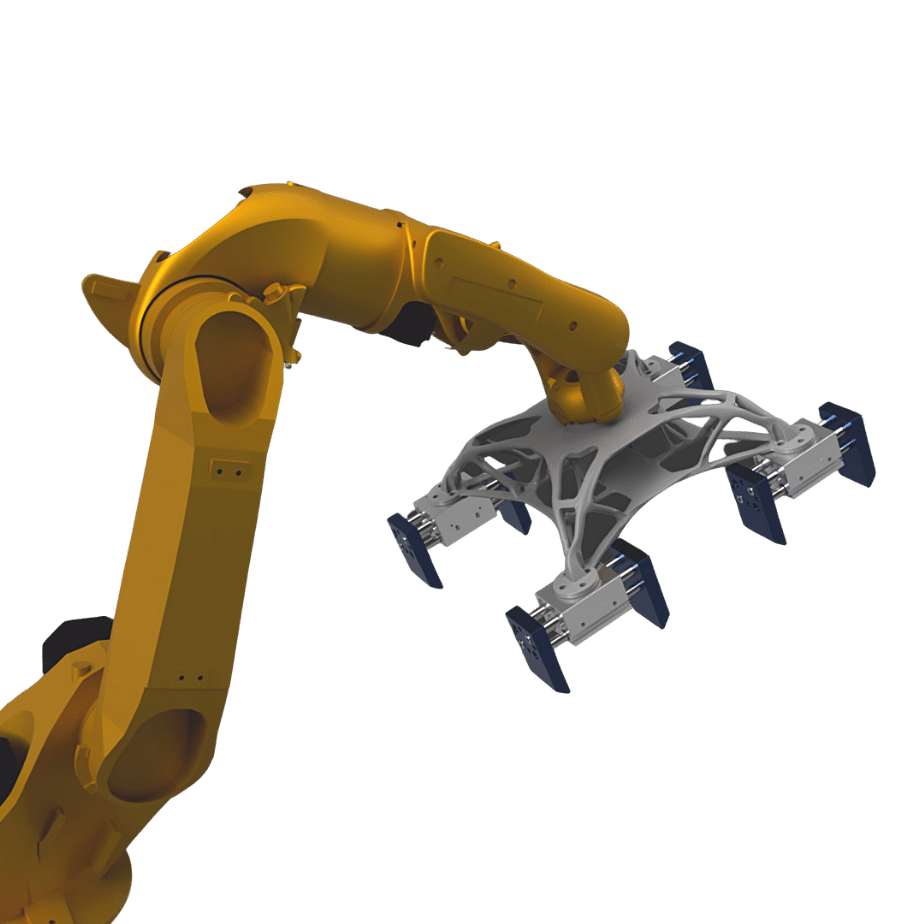

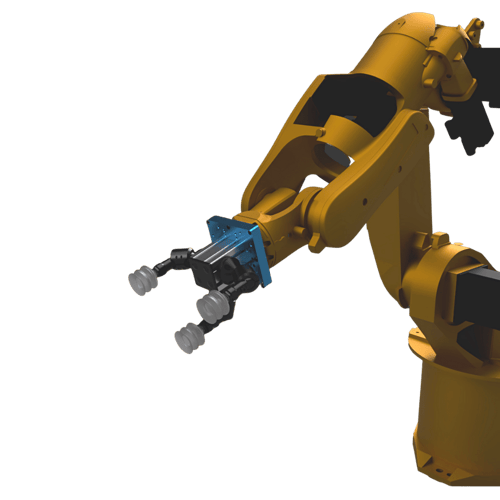

The ever-rising demand for robotics in the manufacturing industry has led to a dramatic increase in the numbers, styles, and complexity of end-of-arm tools (EOAT).

Our team of engineers designs EOATs for material handling between cells and stations, machine (un)loading, screw installation, assembly, adhesive/sealant applications, cutting and deburring applications, and many more.

What are End of Arm Tooling Robots (EOAT)?

End of Arm Tooling Robots, or EOATs, are robotic devices that are attached to the end of an industrial robot arm. They are used to grip, hold, and manipulate objects during automated processes.

End of arm tooling (EOAT) is a key component of robotic technology. It refers to the equipment that interacts with parts and components at the end of a robot arm, for example.

Why should you custom design an EOAT?

Custom-designed EOATs can be created to perfectly match the needs of a specific application. This can lead to increased efficiency and productivity in the workplace.

Custom-designed EOATs can provide many benefits over off-the-shelf solutions. For example, custom EOATs can be designed for specific applications, which can lead to increased efficiency and productivity.

End Of Arm Tooling Design Services

From the simplest to the most complex toolings, our EOAT engineers can design a tooling to suit your specific application.

- Gripper selection and design

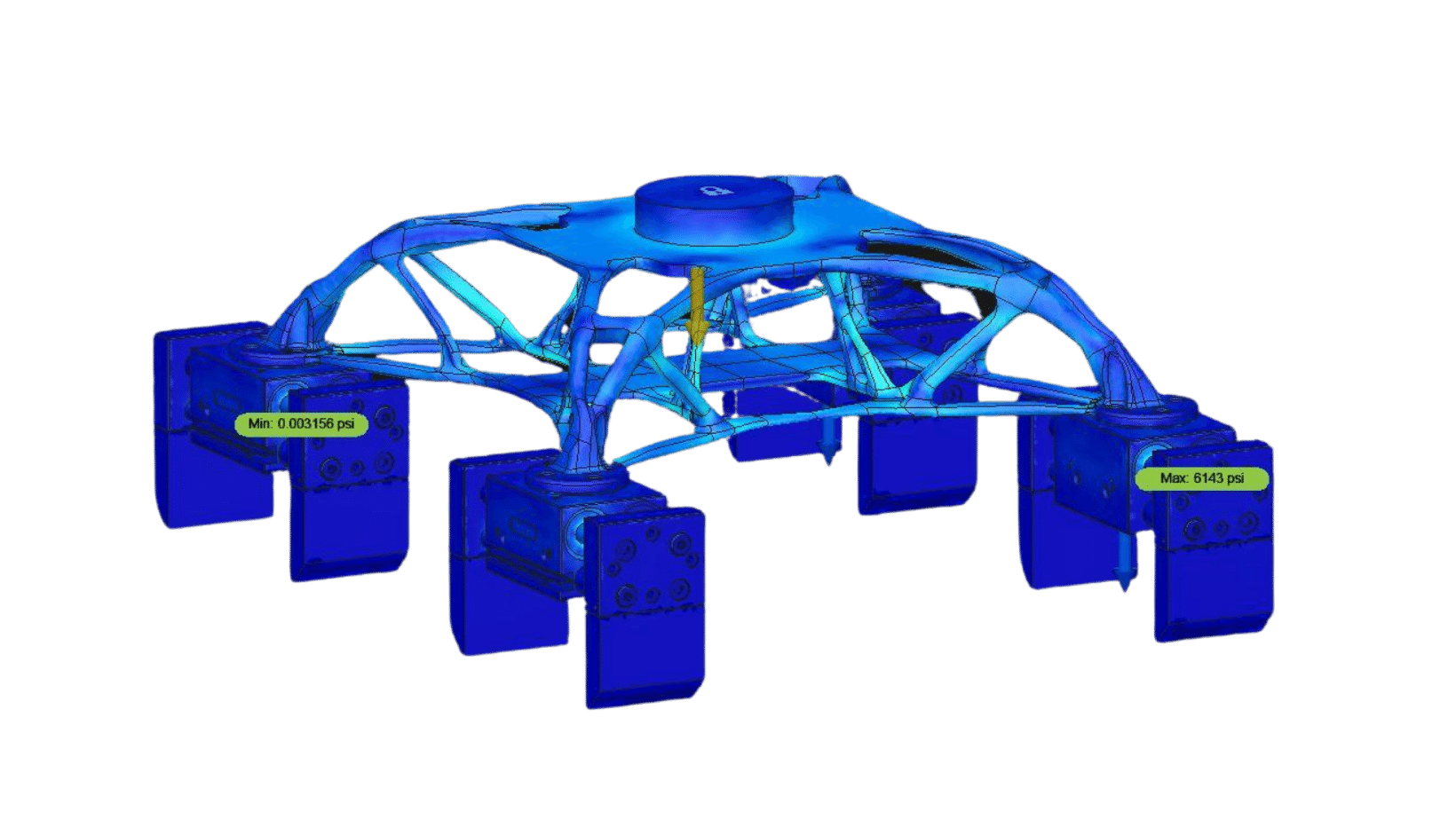

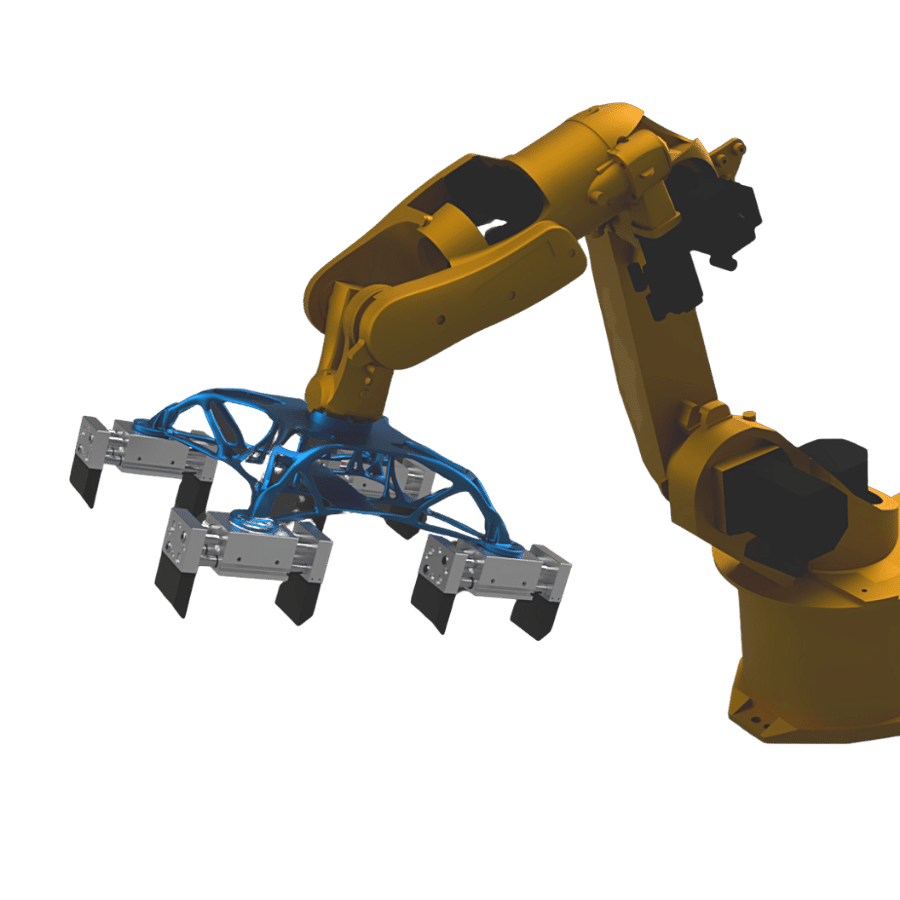

- End effector weight optimization with generative design

- Carbon fiber chassis design for reduced weight (special case)

When designing EOATs

When designing EOAT for robotic applications, our team considers the following factors:

Loading

Manipulator Speed

Forces and Inertia

Acceleration

Orientation

Operating Environment

Tool PLC programing and integration with Robot