Lower Operating Costs

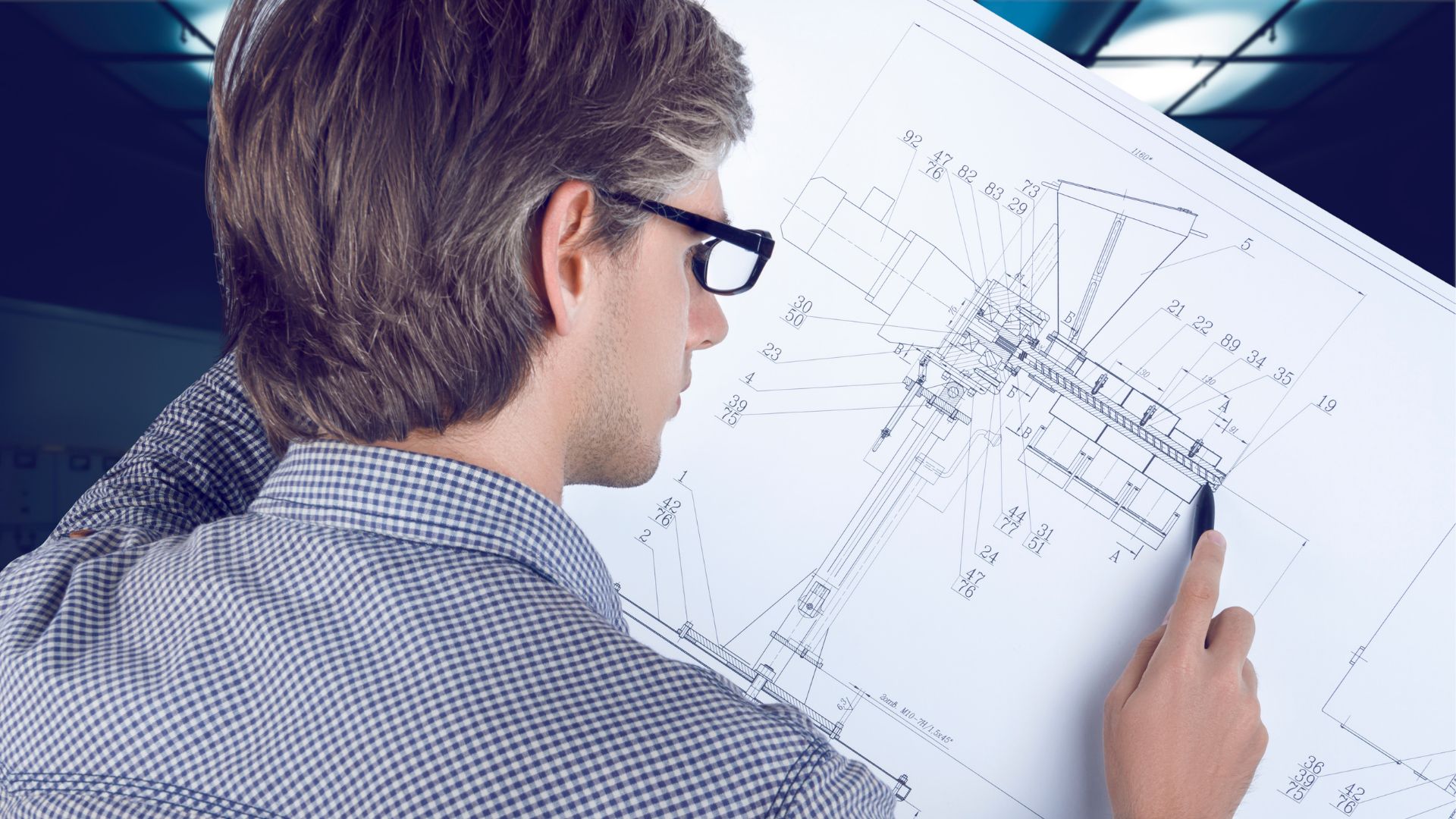

Cut costs with custom automation.

We design and retrofit machines, integrate FANUC robotics, and build automated systems that reduce waste and labor.

Flexible, full-cycle engineering solutions without the overhead - powered by a trusted network of expert engineers and industrial suppliers.

Nevatio Engineering delivers scalable automation systems including machine retrofits, automated manufacturing technology, and robotics integration to help manufacturers cut costs, improve logistics and increase production.

Cut costs with custom automation.

We design and retrofit machines, integrate FANUC robotics, and build automated systems that reduce waste and labor.

Automate the repetitive.

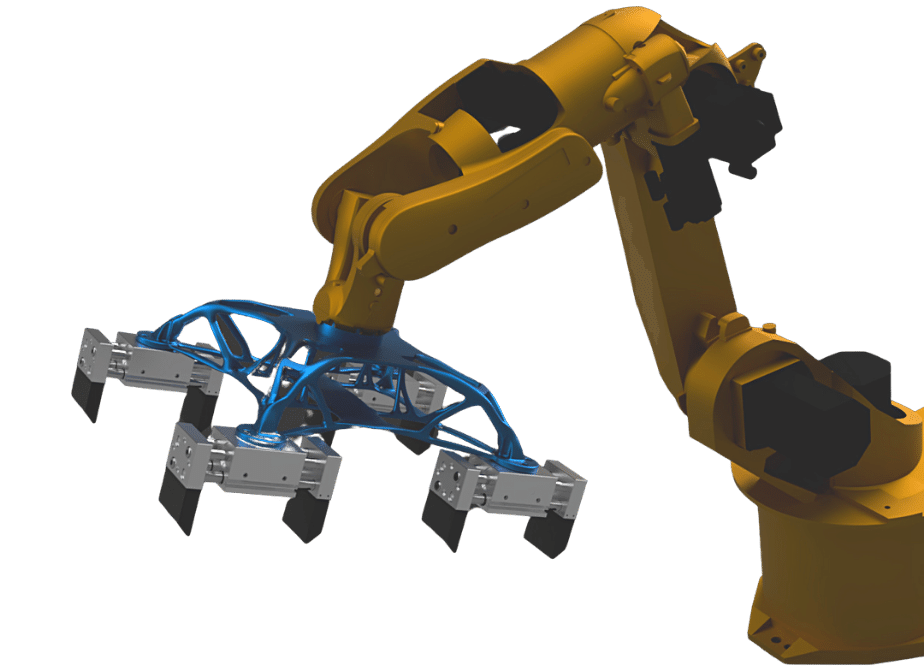

From pick-and-place robots to end-of-arm tooling and material handling automation, we help you streamline production at scale.

Smarter systems. Safer teams.

Industrial automation and custom safety fixtures reduce risk while maintaining precision and control on your factory floor.

Build faster, scale smarter.

Accelerate throughput with assembly line automation, automated packaging systems, and robotics integration tailored to your workflow.

As a FANUC Authorized System Integrator, Nevatio Engineering delivers advanced robotic automation across industries like manufacturing, logistics, aerospace, and automotive.

Our team integrates FANUC systems that streamline production, boost accuracy, and scale with your operation.

-1.png?width=345&height=334&name=FANUC%20-%20ASI%20(1)-1.png)

We offer on-demand access to expert engineers, advanced design tools, and custom manufacturing support. Whether you need mechanical design, reverse engineering, or robotic systems integration, we’ll help you build smarter and faster.

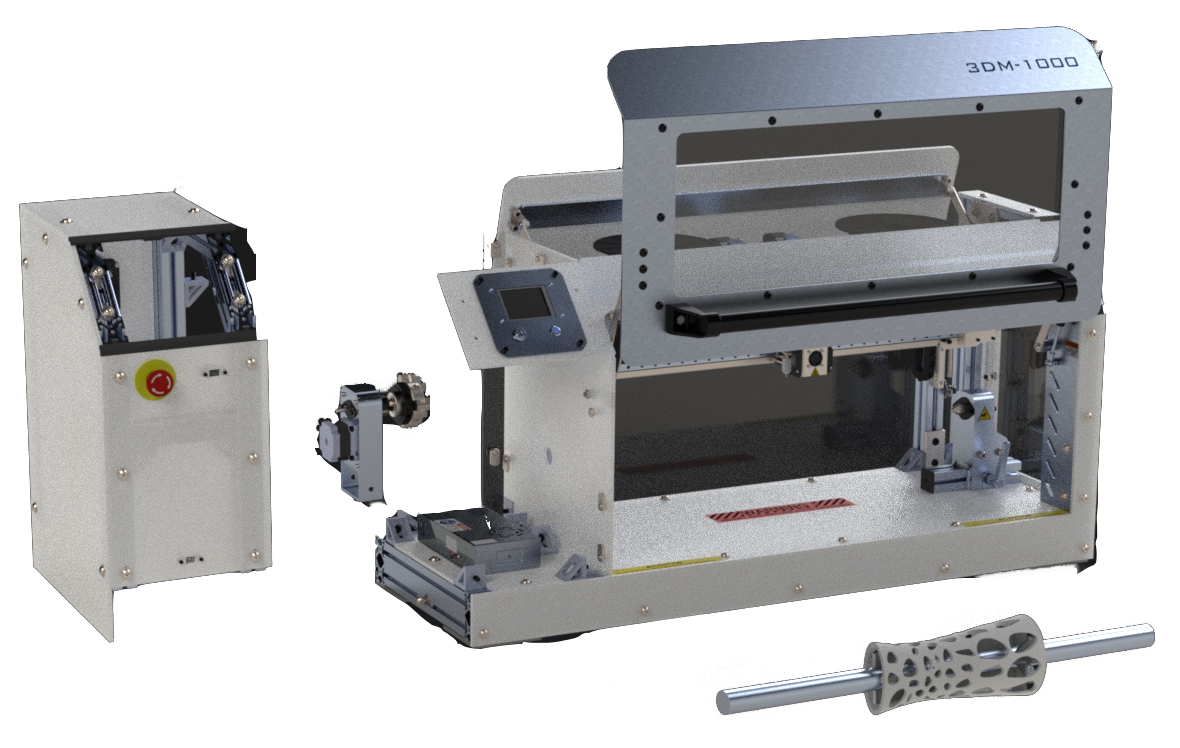

We design and build custom machines for automated manufacturing, assembly, and production. From 3D printers to robotic sorting systems, our solutions are built for efficiency and precision.

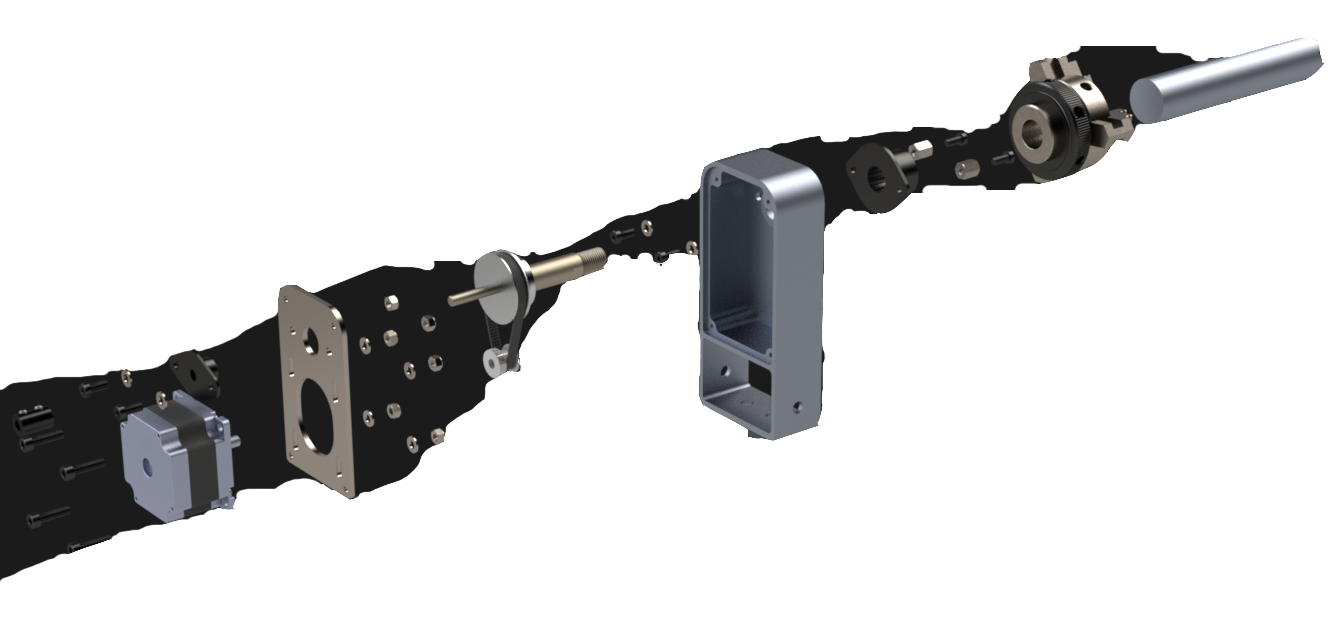

Machine retrofitting is one of our most in-demand services. We specialize in upgrading existing equipment with automation, control systems, and robotics integration - extending machine life, improving performance, and enabling new capabilities without compromising core functions.

We design and build unique devices tailored to complex engineering challenges. From prototyping to redesign, our team delivers custom solutions for specialized applications that fall outside standard automation systems.

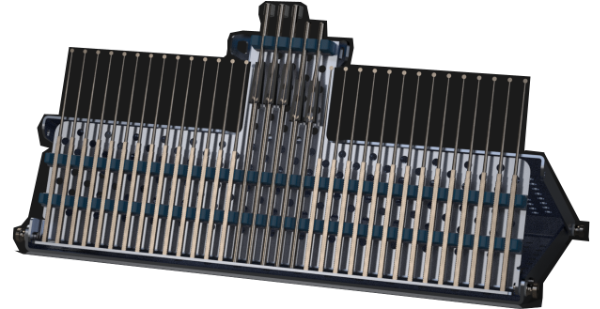

We provide custom jigs and fixtures designed for automated manufacturing, CNC machining, and robotic assembly. Built to your specifications, our tooling solutions improve accuracy, speed, and consistency across production and prototyping environments.

Nevatio specializes in designing and integrating advanced automation and control systems for manufacturing and industrial applications. We use PLC- and PC-based technology with open architecture, remote diagnostics, and predictive maintenance to deliver reliable, scalable automation solutions.

We design custom EOAT solutions for robotic automation, material handling, machine loading and unloading, assembly, screw driving, adhesive application, cutting, deburring, and more. Our end-of-arm tools are engineered to optimize precision and efficiency in automated manufacturing systems.

As a FANUC Authorized System Integrator, we design and deploy custom robotic automation systems built around high-performance FANUC robots. From pick and place applications to palletizing, welding, and material handling automation, we deliver scalable robotic solutions engineered for precision, efficiency, and long-term reliability.

%20(14)%20(1).png?width=500&height=500&name=Hero%20Image%20-%20Nevatio%20(500%20%C3%97%20500%20px)%20(14)%20(1).png)

Design concepts using CAD modeling tools for automated manufacturing systems and industrial product development.

Custom part and system-level engineering to support industrial automation solutions and robotics integration.

From concept to physical prototypes, accelerating product development for automation-ready components.

Simulation and stress testing to ensure performance and durability in automated manufacturing environments.

Rebuilding or improving existing components for machine retrofits, control systems, or robotics integration.

Innovating new technologies and refining designs for use in robotic process automation and custom machinery.

Comprehensive schematics and system layouts for automation and control systems used in industrial automation and automated manufacturing environments.

Custom printed circuit board (PCB) layouts developed for embedded devices, sensor integration, and robotic control systems.

Low-level programming and firmware development to support precise hardware control within automated systems and intelligent machinery.

Development in C++, Visual Basic, JavaScript, Python, and more—enabling flexibility in programming embedded systems, industrial robotics, and automation equipment.

%20(15)%20(1).png?width=175&height=175&name=Hero%20Image%20-%20Nevatio%20(500%20%C3%97%20500%20px)%20(15)%20(1).png)

Custom control logic development using major platforms for precise machine and process automation.

Design and fabrication of UL-compliant control panels for automated manufacturing systems, industrial robotics, and material handling.

Engineering and installation of robust power systems to support control panels, PLCs, actuators, and high-load automation equipment.

Integration of machine safety features including e-stops, light curtains, lockout-tagout systems, and functional safety compliance.

End-to-end integration of hardware, software, and robotics—including FANUC robots, sensors, HMIs, and other automation components.

Our added knowledge in industry design standards such as ASME, ANSI, ISO, NFPA, NEC and BS allows us to quickly integrate our services with your existing standard design processes, keeping your resources free from unnecessary rework.

.png?width=501&height=500&name=certs%20white%204%20(2).png)

Nevatio engineers designed and built special equipment that allows any one of our employees to lift and load 200lbs vinyl rolls onto the machine with ease, which opened up our scope for the type of people we can hire. They provide unique solutions to unique problems as well as retrofitting our existing machines with upgrades.

We were approached to design two unique forklift attachments by an established client. With our time and resources tied up in other projects, we reached out to Nevatio Engineering for assistance in the design and development of the attachments. They were very inventive, collaborative and responsive, with a quick turnaround at each phase. Nevatio improved on our previous concepts and “wowed” the client with interactive 3D renderings of the tools.

-1.png?width=209&height=100&name=Logos%20-%20Nevatio%20(1)-1.png)

Nevatio was able to provide detailed modeling and testing for the initial job for InSyte to assemble an industrial design guide for its product for customers. With fast turn-around and clear communication, Nevatio continues to be InSyte’s choice for its mechanical and systems engineering design needs.